I. Aluminium sheet metal fabrication

I. Aluminium sheet metal fabricationAluminum was discovered in the early 1800s and the Paris World's Fair in 1855 presented the world's first 55kg block of aluminum. That time its price was a rival to gold's due to the difficulties in production, so at the beginning aluminium was used for making jewellery.

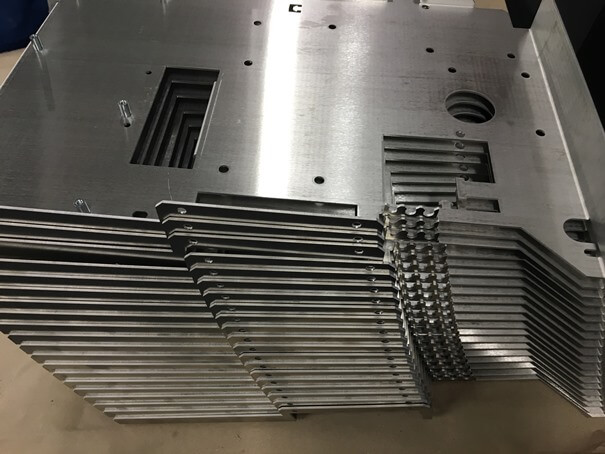

Since then aluminium is used on many fields because of its advantageous features. We at Melior Laser also happy to work with aluminium as it is easily processable, attractive surfaces and spectacularly sharp bends can be obtained with this material. However, there are some aspects must be taken into consideration during aluminium sheet metal fabrication:

1, Certain aluminium alloys must be used in a given time (normally within 6 months). Over this time its mechanical properties can be changed and not all requirements of formability can they meet.

2, In case of nibbling and punching a coated tool is necessary.

3, During bending, if bending mark is to be avoided, a special tool should be used.

4, During aluminium laser cutting the energy demand is great and we must pay close attention to burr-free edges and splash-free surfaces.

5, Aluminum welding requires special expertise.

6, When grinding aluminium the secondary burr is to avoided.

Keeping all these criteria in mind aluminium is one of our favourite material. The following technologies are applied during aluminium fabrication: aluminium laser cutting, bending, fastener insertion, smaller machining works, stud welding, grinding and surface treatment (powder coating and anodising).

Keeping all these criteria in mind aluminium is one of our favourite material. The following technologies are applied during aluminium fabrication: aluminium laser cutting, bending, fastener insertion, smaller machining works, stud welding, grinding and surface treatment (powder coating and anodising).

II. Aluminium alloys used by Melior Laser

EN AW 5754

EN AW 5052

EN AW 6082

Here you can find our material list: Sheet metal material guide

Characteristics of the material are as follows:

It has medium strength, very good corrosion resistance and very good chemical resistance. This material has excellent weldability, the welding seams have almost the same corrosion resistance than of the raw material. Its processability with cutting tools in hardened state is suitable. It has good formability.

Preferable sheet thicknesses by us: 1 mm - 8 mm.

For our automotive partner EN AW 6082 material is the most typical, usually with T4 heat treatment condition. After heat treatment its mechanical properties are still excellent. It is medium duty material, mainly used for parts operating between -70 and +50 °C temperature.

Our extensive aluminium sheet metal fabrication experience enables us to manufacture aluminium parts for a wide range of industry segments.

For our automotive partner EN AW 6082 material is the most typical, usually with T4 heat treatment condition. After heat treatment its mechanical properties are still excellent. It is medium duty material, mainly used for parts operating between -70 and +50 °C temperature.

Our extensive aluminium sheet metal fabrication experience enables us to manufacture aluminium parts for a wide range of industry segments.