I. Popular technology

Over the last few years, this technology has become increasingly popular among our customers, and we witness a growing demand for it. The sheet metal parts manufactured by us will be complete and ready for installation with this technological step. At the same time, this is a very "delicate" technology: our partners have very high demands on the quality of powder coating. This procedure is not yet available at Melior in-house but in recent years through a consistent supplier selection process we have found a supplier partner who can meet these expectations.

II. About the technology

During the process, electrostatically charged, colored plastic powder based paint is blown to the part with a powder spraying device. Thus the sheet metal part attracts the dye powder. In the next step, the part is placed in an oven where the paint applied is melted at 160 - 200 ° C.

Over the last few years, this technology has become increasingly popular among our customers, and we witness a growing demand for it. The sheet metal parts manufactured by us will be complete and ready for installation with this technological step. At the same time, this is a very "delicate" technology: our partners have very high demands on the quality of powder coating. This procedure is not yet available at Melior in-house but in recent years through a consistent supplier selection process we have found a supplier partner who can meet these expectations.

II. About the technology

During the process, electrostatically charged, colored plastic powder based paint is blown to the part with a powder spraying device. Thus the sheet metal part attracts the dye powder. In the next step, the part is placed in an oven where the paint applied is melted at 160 - 200 ° C.

III. The benefits of electrostatic powder coating

- Provides a more durable surface

- Usually a single layer is applied, so it'sa faster technology, as there is no drying time

- A wide variety of unique colors and textures can be mixed according to the customer's requirements

- Extremely smooth surface (either horizontally or vertically) can be gained, because the paint is sprayed onto the surface of the part and heated. There is no dripping or other trace of the process.

- Environmentally friendly, because no solvent is used

- There is no release of pollutants due to the use of closed chambers procedure

- UV resistant

- Provides a more durable surface

- Usually a single layer is applied, so it'sa faster technology, as there is no drying time

- A wide variety of unique colors and textures can be mixed according to the customer's requirements

- Extremely smooth surface (either horizontally or vertically) can be gained, because the paint is sprayed onto the surface of the part and heated. There is no dripping or other trace of the process.

- Environmentally friendly, because no solvent is used

- There is no release of pollutants due to the use of closed chambers procedure

- UV resistant

IV. What is the challenge in powder coating?

Beside the benefits, what is the difficulty in powder painting sheet metal parts?

The challenge is that the powder coating process results in a relatively thick coating, yet the demand from customers is often a thin coating. Its high quality production is difficult due to the uneven coating on the polymer blend.

Another, not negligible, point is that, due to the complexity of the technology (there is a need for spray material, electrostatic booths, ovens, etc.), for a smaller set of sheet metal parts it is a costly process.

At the same time, its popularity rises because it is the right solution for those customers where the aesthetic features of the end product have high priority.

The challenge is that the powder coating process results in a relatively thick coating, yet the demand from customers is often a thin coating. Its high quality production is difficult due to the uneven coating on the polymer blend.

Another, not negligible, point is that, due to the complexity of the technology (there is a need for spray material, electrostatic booths, ovens, etc.), for a smaller set of sheet metal parts it is a costly process.

At the same time, its popularity rises because it is the right solution for those customers where the aesthetic features of the end product have high priority.

V. The most important features of the powder coating coating

If our customers decide on the powder coating as the appropriate coating method for them, they are asked for the following information in their order:

- RAL color code

- Thickness (the end product will be used indoor or outdoor)

- Brightness: matte, silk or shiny

- Structure is smooth, fine or normal

- The mounting point on the part during painting

- Quality requirements (high, normal, low), depending on the type of end product that is incorporated into the sheet metal part

- RAL color code

- Thickness (the end product will be used indoor or outdoor)

- Brightness: matte, silk or shiny

- Structure is smooth, fine or normal

- The mounting point on the part during painting

- Quality requirements (high, normal, low), depending on the type of end product that is incorporated into the sheet metal part

For powdered sheet metal parts, it is possible to specify more detailed requirements:

On request, our partner (an accredited laboratory) a full mechanical and corrosion test of the paint coatings can performed. Some examples of the most common tests: hardness test (Pencil, Buchholz type), brightness measurement, salt spray test, etc.

On request, our partner (an accredited laboratory) a full mechanical and corrosion test of the paint coatings can performed. Some examples of the most common tests: hardness test (Pencil, Buchholz type), brightness measurement, salt spray test, etc.

VI. Points to be considered when applying powder painting

Melior Laser, together with the supplier partner places great emphasis on high-quality parts. For this many aspects have to be taken into consideration when designing and manufacturing parts, the most important of which are listed below:

Designing:

Sharp corners,edges and bents are to be avoided. Hanging holes or threaded pins are required to hang the parts during process. Due to the nature of the component, it can deform or fade during heating.

Laser Cutting:

For powder-coated parts, laser cutting with nitrogen is used to prevent oxidation of the cut edge, which must be removed mechanically or chemically before powser sparaying. Otherwise the oxide layer will prevent proper adhesion to the surface.

Surface preparation:

Only clean, scratch-free metal parts can be produced in high quality. We pay close attention that the parts are rust-, oxid-, grease- and oil residue-free.

Melior Laser, together with the supplier partner places great emphasis on high-quality parts. For this many aspects have to be taken into consideration when designing and manufacturing parts, the most important of which are listed below:

Designing:

Sharp corners,edges and bents are to be avoided. Hanging holes or threaded pins are required to hang the parts during process. Due to the nature of the component, it can deform or fade during heating.

Laser Cutting:

For powder-coated parts, laser cutting with nitrogen is used to prevent oxidation of the cut edge, which must be removed mechanically or chemically before powser sparaying. Otherwise the oxide layer will prevent proper adhesion to the surface.

Surface preparation:

Only clean, scratch-free metal parts can be produced in high quality. We pay close attention that the parts are rust-, oxid-, grease- and oil residue-free.

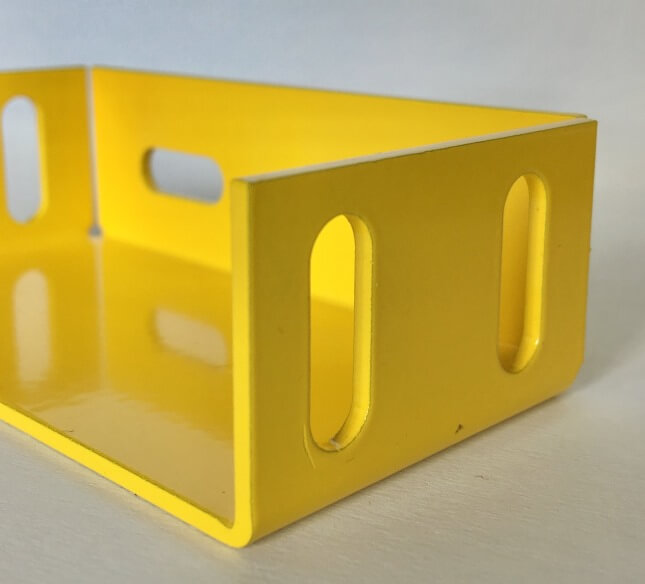

*Index photo: Copyright: sspopov / 123RF Stock photo